Production Capacity

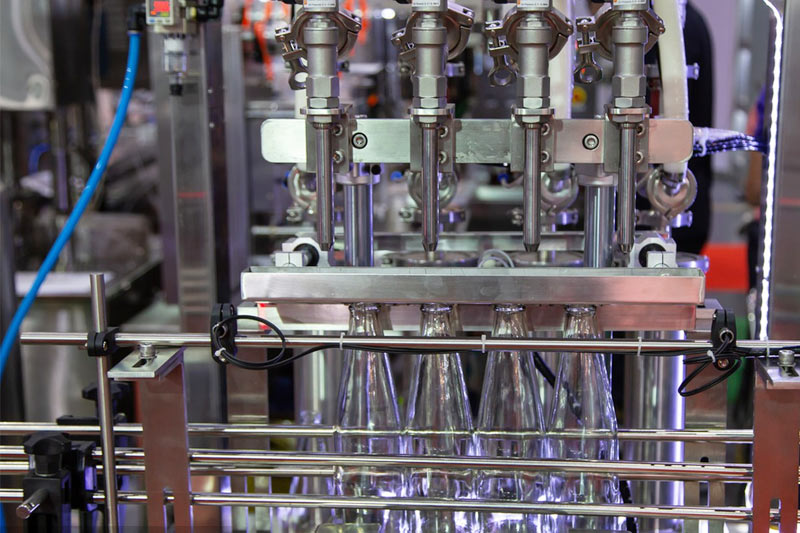

Container Types and Sizes

Filling Speed and Accuracy

Carbonation Management

Automation and Control

Cleanliness and Hygiene

Maintenance and Support

Cost and Return on Investment

Conclusion

Fabricante de equipos para fábricas de cerveza Los suministros de elaboración de cerveza proporcionados por Micet Craft pueden satisfacer sus necesidades de elaboración de cerveza,

China fabricante y proveedores de equipos de elaboración de cerveza Micet Craft ha colaborado con cervecerías de muchos países del mundo para suministrarles equipos de

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life

Tanque de cerveza brillante profesional fabricante de China El tanque brillante es un recipiente para almacenar y carbonatar la cerveza, también se le llama tanque

El mejor fabricante de sistemas de elaboración de cerveza de china Micet Craft es un fabricante profesional de sistemas de elaboración de cerveza en China.

Clasificación de la máquina de llenado de cerveza La máquina llenadora de cerveza es el equipo central de la línea de producción de cerveza. Nuestro

Fabricante de equipos para fábricas de cerveza Los suministros de elaboración de cerveza proporcionados por Micet Craft pueden satisfacer sus necesidades de elaboración de cerveza,

China fabricante y proveedores de equipos de elaboración de cerveza Micet Craft ha colaborado con cervecerías de muchos países del mundo para suministrarles equipos de

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life

Tanque de cerveza brillante profesional fabricante de China El tanque brillante es un recipiente para almacenar y carbonatar la cerveza, también se le llama tanque

El mejor fabricante de sistemas de elaboración de cerveza de china Micet Craft es un fabricante profesional de sistemas de elaboración de cerveza en China.

Clasificación de la máquina de llenado de cerveza La máquina llenadora de cerveza es el equipo central de la línea de producción de cerveza. Nuestro