Open-Top Fermenters

Closed Conical Fermenters

Unitank Fermenters

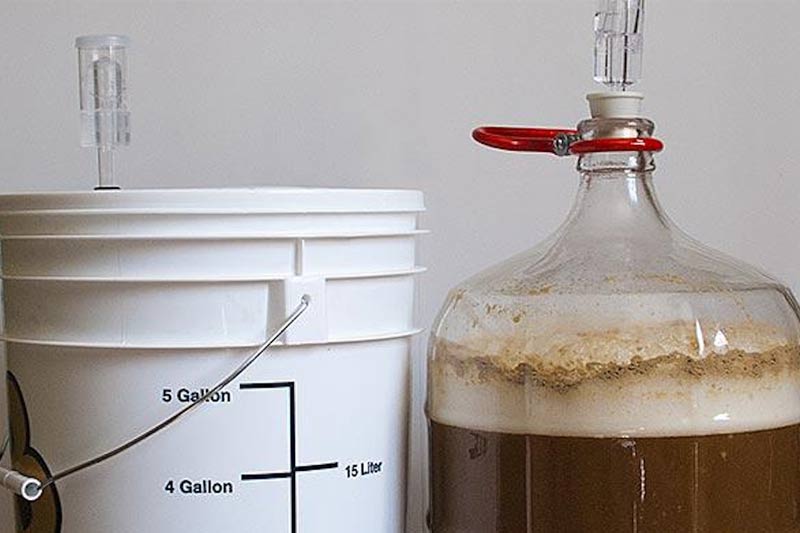

Plastic Fermenters

Barrel Fermenters

Horizontal Fermenters

Conclusion

Fabricant d’équipement de brasserie Le matériel de brassage fourni par Micet Craft peut répondre à vos besoins en matière de brassage, qu’il s’agisse de petits

Fabricant professionnel de réservoirs à bière en Chine Le bright tank est un récipient destiné à stocker et à carboniser la bière, il est également

Classification de la machine de remplissage de bière La machine de remplissage de bière est l’équipement de base de la chaîne de production de bière.

Fabricant et fournisseurs d’équipements de brassage en Chine Micet Craft a coopéré avec des brasseries dans de nombreux pays du monde pour leur fournir du

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life

Meilleur fabricant de système de brassage de bière de Chine Micet Craft est un fabricant professionnel de systèmes de brassage de la bière en Chine.

Fabricant d’équipement de brasserie Le matériel de brassage fourni par Micet Craft peut répondre à vos besoins en matière de brassage, qu’il s’agisse de petits

Fabricant professionnel de réservoirs à bière en Chine Le bright tank est un récipient destiné à stocker et à carboniser la bière, il est également

Classification de la machine de remplissage de bière La machine de remplissage de bière est l’équipement de base de la chaîne de production de bière.

Fabricant et fournisseurs d’équipements de brassage en Chine Micet Craft a coopéré avec des brasseries dans de nombreux pays du monde pour leur fournir du

Best brewhouse equipment manufacturer from china Brewing good beer requires brewhouse equipment. Whether you are brewing beer for home, business or brewery, Micet Craft can

China stainless steel fermentation vessels manufacturer The fermentation tank is where the beer carry out the fermentation process, it provides a place suitable for life

Meilleur fabricant de système de brassage de bière de Chine Micet Craft est un fabricant professionnel de systèmes de brassage de la bière en Chine.