Kombucha, a fermented tea rich in probiotics, has set off a new trend of healthy drinks around the world. As consumers’ enthusiasm for natural, low-sugar, and intestinal health drinks continues to heat up, more and more people are trying to make their kombucha at home or in commercial places. In order to successfully brew kombucha with pure flavor, active strains, and safe and controllable, suitable kombucha brewing equipment is an indispensable part.

Basic principles of Kombucha brewing

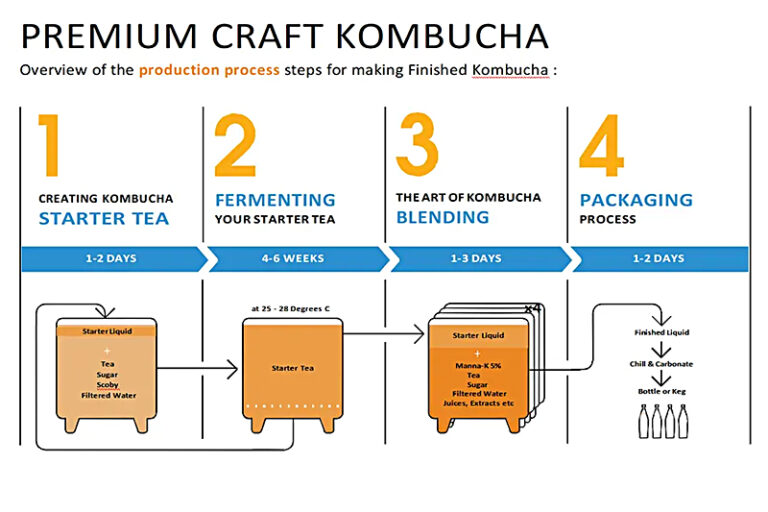

Kombucha brewing is a fermentation process involving tea, sugar, and “Scoby” (Symbiotic Culture Of Bacteria and Yeast). Through the decomposition of sugar, organic acids, bubbles, and trace alcohol are produced, thus forming its unique sweet and sour taste and probiotic function. In order to ensure that this fermentation process is smooth and controllable, professional Kombucha brewing equipment is essential.

Professional kombucha brewing equipment

Fermentation container

This is the core equipment for kombucha brewing, which is used to hold tea liquid, sugar and Scoby for fermentation. The material and design of the container directly affect the hygiene, safety and flavor of the fermentation.

- Recommended materials: glass, stainless steel (316L), ceramic. Glass is convenient for observing the fermentation process and is suitable for home use; stainless steel is acid-resistant and corrosion-resistant, suitable for commercial mass production.

- Capacity selection: Most families use 1~5 liter; commercial production often uses 50, 100, or even thousands of liters of professional fermentation tanks.

- Structural features: High-quality commercial fermentation tanks are equipped with liquid outlets, cleaning ports, and sealing devices for easy operation and maintenance.

Temperature control equipment

Kombucha fermentation is sensitive to temperature, and the most suitable temperature range is 24°C~29°C. Temperature control equipment can help stabilize the fermentation speed and improve flavor consistency.

- Home equipment: heating pads, fermentation thermostats heating belts, etc., are simple and easy to operate.

- Commercial systems: automatic constant temperature heating/cooling devices built into the fermentation tank, or set up a constant temperature environment room to ensure stable fermentation of the entire batch of products.

Filtration and filling equipment

After fermentation, kombucha needs to be filtered, filled and sealed for storage and sale.

- Filter: used to remove residual Scoby debris and sediment to keep the drink clear.

- Filling equipment: from manual funnel filling to semi-automatic/fully automatic filling machines, can be selected according to production. Commercial filling lines are usually equipped with capping machines and labeling machines to improve production efficiency.

- Carbon injection system (optional): add artificial carbonation to kombucha to improve the taste level.

Cleaning and disinfection tools

Kombucha is a microbial fermentation product, and sanitation is extremely important. Cleaning and disinfection equipment is the key to preventing contamination.

- Household appliances: simple tools such as edible white vinegar, warm water, and disinfection brushes are sufficient.

- Commercial system: CIP online cleaning system, which realizes automatic cleaning of containers, pipes, etc., greatly improving efficiency and safety.

Monitoring and control tools

To ensure that the fermentation process is controllable, the following detection tools are often used:

- pH meter: monitors acidity to prevent over-fermentation or fermentation failure.

- Thermometer: real-time grasp of the fermentation environment temperature.

- Brix meter: used to monitor sugar changes and determine the progress of fermentation.

Things to note when choosing kombucha brewing equipment

Safety and food grade standards

When choosing kombucha brewing equipment, the first thing to consider is food safety. Since kombucha is a fermented beverage that is drunk directly, all equipment materials that come into contact with raw materials and fermentation liquid must meet food-grade standards. It is recommended to use food-grade stainless steel, acid-resistant glass, or unglazed ceramics, and avoid using ordinary plastics or coated metals to avoid producing harmful substances during the fermentation process and affecting the safety of the beverage.

Hygiene and cleaning convenience

Whether the equipment is easy to clean and maintain is also an important factor that cannot be ignored. Kombucha is very susceptible to bacterial contamination during the fermentation process, so the brewing equipment must be easy to clean thoroughly to avoid sanitary dead corners. Whether it is household or commercial equipment, a good structural design should help users clean and disinfect regularly to ensure that the fermentation process is always in a controllable and sanitary environment. Commercial equipment should consider whether it has a CIP system to improve efficiency and reduce labor costs.

Output and scalability

Production requirements are also an important consideration when purchasing equipment. The capacity of the equipment should match the actual production volume of the user, and a certain amount of expansion space should be reserved. Small brewers who are just starting, can start with small and medium-sized equipment and gradually expand the scale according to market response. For brands that plan to operate for the long term, the modularity and scalability of the equipment will determine whether they can make a smooth transition when expanding production in the future.

Convenience and automation of operation

The convenience of operation directly affects brewing efficiency and personnel training costs. For home users, the equipment should be as simple and intuitive as possible, easy to use and experiment; while in commercial applications, the degree of automation will significantly affect the consistency of fermentation and management costs. Equipment with functions such as temperature control system, automatic filling, digital monitoring, etc., although the initial investment is slightly higher, is more stable and productive in daily operation.

Brand and after-sales service

The cost performance and brand service should not be ignored. Brewing equipment is usually not a one-time tool, but a part of long-term investment and operation. Therefore, when purchasing, you should not only compare the price but also pay attention to whether the manufacturer has professional experience, and whether it provides technical support, warranty service, and post-maintenance. A set of equipment with stable quality and perfect after-sales service will bring twice the result with half the effort to kombucha brewing.

Recommended combination of kombucha brewing equipment

Depending on the scale and purpose of kombucha brewing, the equipment configuration requirements will also vary. Whether it is a home enthusiast, a start-up workshop, or a large-scale production enterprise, you can choose a suitable equipment combination according to the actual situation to achieve a practical and efficient brewing goal.

- For home users, it is recommended to start with simple and easy-to-operate basic equipment. A set of basic glass fermentation tanks, with breathable cotton cloth and rubber bands for container sealing, can meet the kombucha production needs of most families. Add a small temperature-controlled fermentation mat or thermostat to maintain a stable fermentation environment, which helps to improve the success rate of fermentation. With pH test paper, a thermometer, and a simple filter, users can start their home fermentation journey. The overall cost is low and the operation is intuitive, suitable for entry and daily self-drinking.

- For small entrepreneurs or studio-level producers, the equipment combination needs to develop in a more professional direction. It is recommended to use a food-grade stainless steel fermentation tank with a capacity between 50L and 200L, equipped with a bottom drainage structure with a valve to facilitate the transfer of the stock solution after fermentation. In addition, heating or cooling temperature control devices can maintain the consistency of fermentation. In contrast, the addition of semi-automatic filling machines, filters, and bottle cap sealing equipment can significantly improve packaging efficiency. At this stage, basic experimental testing instruments are also essential, such as digital pH meters and sugar meters, to monitor and adjust the fermentation process. This combination is suitable for small-batch operators with small daily shipments but stable product quality.

- For medium and large commercial production units, the selection of brewing equipment is more systematic and automated. Such enterprises usually use professional-grade fermentation tanks of more than 500L, with a complete CIP automatic cleaning system, temperature control circulation system, and a complete set of filtering, filling, labeling, and packaging lines to support continuous and batch high-intensity production needs. At the same time, laboratory-level testing equipment such as automatic pH monitors, microbial incubators, alcohol content analyzers, etc. have also become an important part of quality control. This type of combination requires a large investment, but can significantly improve production efficiency and product consistency, and is suitable for brands or beverage processing plants that already have mature sales channels.