With the rise of craft beer culture, more and more enthusiasts want to be able to brew beer at home or in commercial places. However, successfully brewing a high-quality beer requires not only solid brewing knowledge but also suitable brewing equipment. Whether it is home brewing or commercial production, purchasing suitable brewing equipment is the key to ensuring brewing quality and efficiency.

Overview of Brewing Equipment

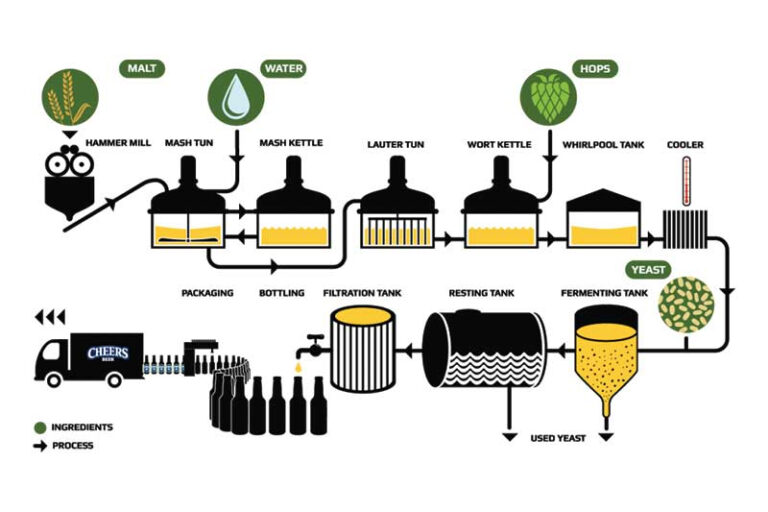

Brewery equipment refers to the machinery and tools used to produce alcoholic beverages (such as beer, liquor, wine, etc.), covering the entire brewing process from raw material processing to packaging. Different types of alcohol require different equipment, but the basic process is similar, including mash, fermentation, maturation, and packaging.

- Raw material processing equipment: used to pre-treat brewing raw materials, such as malt crushers for crushing malt, cooking equipment for cooking rice or grains, and agitators for mixing raw materials. This equipment ensures that the raw materials are suitable for mashand fermentation.

- Brewhouse Equipment: mashis the process of converting starch into fermentable sugars. The main equipment includes mashtun, filter tanks, and boiling pots. The mash tun is used for heating and enzymatic hydrolysis, the filter tank separates the wort, and the boiling pot is used for sterilization and adding hops to add flavor.

- Fermentation equipment: Fermentation is the core link of brewing. The main equipment includes fermentation tanks and temperature control systems. The fermentation tank provides a yeast fermentation environment, and the temperature control system ensures a stable fermentation temperature to ensure the quality of the wine.

- Aging and packaging equipment: Aging equipment such as refrigerated tanks are used to enhance the flavor and stability of the wine, filtration equipment is used to remove sediment, and packaging equipment (such as bottling machines and barrel filling machines) is used for final bottling or barreling for easy storage and sales.

Basic equipment required for beer brewing

Brewhouse Equipment

mash is the first step in brewing beer, and its purpose is to convert starch in malt into fermentable sugars.

- Mash Tun: The mashtun is used to heat and maintain a certain temperature to promote the activity of enzymes and convert starch into sugars. Home brewers can use ordinary stainless steel pots, while commercial brewing usually requires a professional mash tun with an agitator and temperature control system.

- Lauter Tun: The filter tank is used to separate the spent grains and wort. Home brewers can use a mashtun with a filter to complete this step, while large brewing systems are equipped with professional filter tanks to improve filtration efficiency.

- Boil Kettle: The boiling pot is used to boil the wort and add hops to increase flavor and sterilize. When purchasing, you need to consider the heating method (electric heating or gas heating), the potting material (stainless steel is preferred), and whether it is equipped with a temperature control system.

Fermentation Equipment

- Fermentation Tank: Home brewers usually use glass or plastic fermentation tanks, while commercial brewing requires conical stainless steel fermentation tanks with cooling systems to maintain optimal fermentation temperature.

- Airlock: Airlocks are used to release carbon dioxide produced during fermentation while preventing external air from contaminating the wort.

- Cooling System: Fermentation temperature control is critical. Home brewers can use refrigerators or freezers, while commercial brewers usually use cooling jackets or water-cooling systems to maintain a constant temperature.

Aging and packaging equipment

After beer fermentation is completed, it needs to be aged and packaged to enhance the flavor and facilitate storage and sales. Common equipment includes:

- Bright Beer Tank: Aging tanks are used to further clarify and carbonate beer. Commercial brewing is often equipped with stainless steel refrigerated tanks with pressure control devices.

- Filtering System: Used to remove yeast and sediment to improve the clarity of beer. Small brewers can use simple filters, while commercial brewing usually uses plate and frame filters or membrane filtration equipment.

- Bottling Equipment: Depending on the packaging method, manual or automatic bottling equipment, can-filling machines, or beer barrel-filling equipment can be selected. Commercial brewing needs to be equipped with efficient automatic filling lines to improve production efficiency.

How to choose the right brewing equipment?

When purchasing brewing equipment, you should consider the brewing scale, budget, ease of operation, and future development plans. The following are purchase recommendations for brewers at different levels:

Home brewers (beginners)

- mashpot: Choose a stainless steel pot with a capacity of 10-20 liters and a thermometer.

- Fermentation tank: You can choose a glass or food-grade plastic fermentation tank. The capacity should be slightly larger than the amount of work to prevent overflow.

- Cooling system: You can use an ice bath or immersion cooling coil (Immersion Chiller) to quickly cool the wort.

- Packaging equipment: Manual bottling machines and bottle capping machines are sufficient for small-batch production.

Advanced home brewers (small craft brewing)

- Integrated brewing equipment: such as electric brewing systems (such as Grainfather, BrewZilla), which integrate mash, filtration, boiling, and cooling, and are easy to operate.

- Stainless steel fermentation tanks: equipped with temperature control systems, which facilitate precise control of fermentation temperature.

- Forced carbonation systems: such as CO₂ steel bottles + beer barrels (Corny Keg), improve beer flavor and stability.

Commercial brewers (small breweries or bars)

- Brewhouse system: a stainless steel brewhouse system of at least 500L with automatic temperature control and stirring function is required.

- Conical fermentation tank: with cooling jacket and CIP (cleaning in place) system to ensure hygiene standards.

- Filtration and packaging equipment: choose an automatic filtration system and efficient bottling/kegging equipment to improve production efficiency.

- Quality testing equipment: such as density meter, pH tester, dissolved oxygen analyzer, etc. to ensure stable beer quality.

Equipment Capacity, Spaces, Design, Layout, Customization

When selecting beer brewing equipment, it’s essential to consider capacity, space requirements, design, layout, and customization options. Here’s a detailed table to help you make informed decisions:

EQUIPMENT TYPE | CAPACITY RANGE | SPACE REQUIREMENTS | DESIGN OPTIONS | CUSTOMIZATION |

Fermentation Vessels | 1 gallon to 30 barrels | Varies by size | Glass, plastic, stainless steel | Custom fittings, ports, and valves |

Brewing Kettles | 5 gallons to 60 barrels | Varies by size | Aluminum, stainless steel, electric | Custom ports, integrated heating elements |

Mash Tuns | 5 gallons to 60 barrels | Varies by size | Insulated coolers, stainless steel | False bottoms, sparge arms, insulation |

Heat Exchangers | 5 gallons to commercial-scale volumes | Compact | Plate, counterflow | Customized for specific brewing systems |

Pumps | Varies based on system needs | Small footprint | Magnetic drive, self-priming | Variable speed control, temperature tolerance |

Key considerations for brewing equipment selection

- Material selection: Stainless steel equipment is more durable and easy to clean, while plastic equipment is cheaper but has a shorter lifespan.

- Temperature control capability: Temperature control is essential for fermentation, and equipment with a temperature control system should be selected.

- Scalability: If you plan to expand production in the future, you should consider the scalability of the equipment.

- Brand and after-sales: Give priority to well-known brands, and consider after-sales service and spare parts supply.

- Cleaning and maintenance: Choose equipment that is easy to clean and maintain to reduce the risk of contamination.

FAQ

What is brewing equipment?

Brewing equipment is the tools and machinery used to produce beer, wine, liquor, rice wine, and other alcoholic beverages, covering the entire process from raw material processing, mash, and fermentation to maturation and packaging.

What basic equipment is needed for home brewing?

Home brewing generally requires a mash tun, a fermentation tank, a temperature control system, an airlock, cooling equipment (such as cooling coils) bottling tools, etc.

How to choose a suitable mash tun?

When choosing a mash tun, you should consider the capacity (matching the planned brewing batch), material (stainless steel is more durable), heating method (electric heating or gas heating), and whether it has a temperature control function.

What are the selection criteria for fermentation tanks?

The material of the fermentation tank can be glass, plastic, or stainless steel. Among them, stainless steel fermentation tanks are more suitable for long-term use and easy to clean. Conical fermentation tanks are more suitable for commercial brewing and can easily remove precipitated yeast.

How long does it take for beer to mature?

The aging time varies depending on the style of beer, generally taking 2-4 weeks, and some special styles (such as lager) may take longer.