In the world of alcohol brewing, brewing equipment is not just a tool, but the creator behind every drop of flavor. Whether you are a home brewing enthusiast or planning to open your craft brewery, understanding the types and choices of commercial brewing systems is an important step from hobby to career.

What is a commercial brewing system?

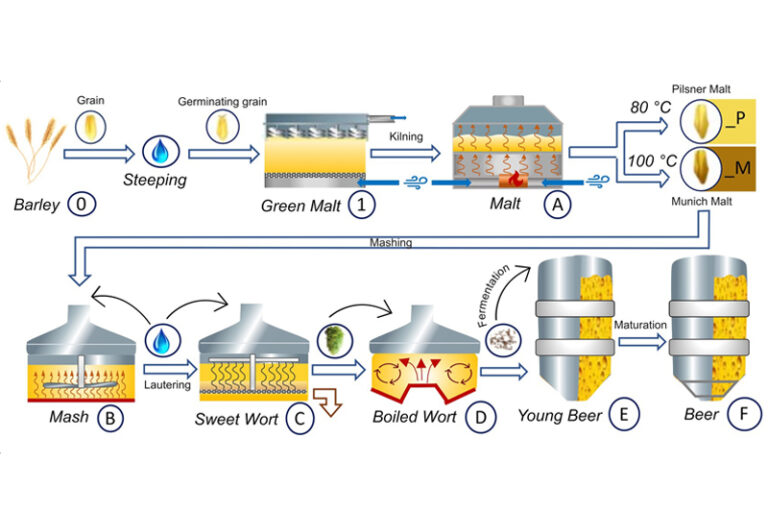

A commercial brewing system is a complete set of equipment used to produce beer, kombucha, wine, or other fermented beverages, mainly used in the commercial operation of wineries, beverage factories, or craft brands. A commercial brewing system can be from crushing grains, mashing, boiling, and fermentation, to finally getting a drinkable beer, each step requires precise control and process support.

Common types of commercial brewing systems

Different types of beverages correspond to different brewing equipment systems. The following are several common types of commercial brewing systems and their characteristics:

Craft beer brewing system

- Main components: brewhouse system, kettle tank, whirlpool tank, hot water tank, fermentation tank, cooling system, control system, CIP system.

- Equipment material:stainless steel (usually SUS304/316).

- Capacity range: from 100L small system to large system above 5000L.

- Applicable scenarios:home brewing, craft brewery, restaurant chain bar.

Kombucha brewing system

- Main components: Kombucha fermentation tank, brewhouse equipment, cooling system, seasoning tank, filling line.

- Key requirements:temperature control system, low oxygen fermentation, easy-to-clean CIP design.

- Applicable scenarios:healthy beverage brands, tea beverage companies, and functional beverage factories.

Wine brewing system

- Main components:destemmed, wine fermentation tank, oak barrel or stainless steel aging tank, cooling device, pressing equipment.

- Special requirements:Grape processing and mild fermentation control need to be considered.

- Applicable scenarios: wineries, wine brand manufacturers, and organic wine brands.

Distillation Equipment

- Main components:mash tun, fermentation tank, distillation equipment, condenser, collector.

- Type: single distillation, double-tower continuous distillation, multi-stage distillation system.

- Applicable scenarios: distilled liquor production enterprises such as whiskey, vodka, brandy, and liquor.

All-in-one brewing system

- Features: A compact design that integrates mashing, boiling, and fermentation.

- Advantages:Space-saving, easy to operate, suitable for start-up brands or small-batch custom production.

- Applicable scenarios:laboratories, R&D centers, boutique bars, start-ups.

The main components of a commercial brewing system

To build a suitable commercial brewing system, you need to understand the role and characteristics of each key link:

Mash Tun

This is the first stop for sugar extraction in the brewing process. The crushed malt is mixed with hot water to convert the starch into fermentable sugar. An efficient mash tun is usually equipped with heating and insulation functions to ensure a stable temperature so that the ideal wort can be extracted.

Lauter Tun

After the mash is complete, the mixture needs to be separated. The lauter tun is equipped with a false bottom, which separates the clear wort from the husk by gravity or stirring. This step determines the cleanliness and efficiency of subsequent brewing.

Kettle tank

This is where the wort is boiled, and hops are added to enhance the aroma and bitterness. The kettle needs to withstand high temperatures and have a good heat exchange design for precise control.

Whirlpool tank

The whirlpool tank concentrates and settles the sediment suspended in the wort after boiling through high-speed rotation, thereby further purifying the wort and improving fermentation efficiency.

Fermentation Tank

This is where the yeast works its magic. Yeast converts sugar into alcohol and carbon dioxide, creating the core flavor of beer. Stainless steel tanks are the first choice for commercial applications because of their hygiene, safety, and ease of temperature control.

Bright Beer Tank

After fermentation, the beer is transferred to the bright beer tank for further carbonation and stabilization in preparation for bottling or tapping. It makes the final product clearer and smoother.

Supporting systems

The supporting systems include pumps, valves, cleaning devices, heat exchangers, temperature control panels, etc. They ensure the coordination and efficiency of the entire brewing process, reduce manual intervention, and improve stability.

How to choose the right commercial brewing systems?

Choosing a commercial brewing system is not “the more expensive the better”, but requires comprehensive consideration of multiple factors such as product positioning, production capacity requirements, budget constraints, etc. The following are recommended selection steps:

Clarify the target output and product type

Is it to produce 100L of kombucha every day? Or 1000L of craft beer per month? Clarifying the demand is the first step. It is recommended to set the target in terms of annual output first, and then break it down into daily/weekly/batch output.

Evaluate the site and usage environment

The system size must match the plant area, especially the floor height, power capacity, and water supply and drainage support. If used in landscape restaurants and bars, the appearance design, and display of the equipment must also be considered.

Determine the operation mode: manual, semi-automatic, or fully automatic

- Manual system: low cost, suitable for tight budget but requires skilled operators.

- Semi-automatic system: balances operation efficiency and cost control.

- Fully automatic system:highly intelligent equipment, suitable for batch standardized production, but with high initial investment.

Choose the material

- 304/316 stainless steel is standard. Observe the welding accuracy, inner surface polishing, and whether it is easy to clean.

- Choose an experienced and fully qualified manufacturer. After-sales service and warranty period are very important.

Choose a system with expansion functions

You can upgrade the temperature control, expand the number of fermentation tanks, reserve CIP interfaces, and add filling lines. The initial investment is controllable, and the later upgrade is convenient to avoid repeated investments.

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Commercial brewing systems cost reference

The difference in equipment investment mainly depends on production capacity, materials, automation level, and manufacturer’s technical capabilities. The following is a rough investment framework (in US dollars):

Scale Type | Capacity range | Cost Estimation |

1-3 BBL | 1 0000 – 2 0000 | |

Small craft brewery | 5-15 BBL | 20 000 – 50 000 |

Regional breweries | 15-30+ BBL | 50 000 – 200000 |

In addition, supporting budgets such as water and electricity upgrades, factory renovations, raw material storage, automatic control systems, and drainage must also be considered.

Routine maintenance tips for commercial brewing systems

Inadequate maintenance is one of the main reasons for shortened equipment life and fluctuating product quality. You can ensure that your equipment is always in good condition by:

- Cleaning on time:rinse the fermentation tank daily and disinfect it thoroughly after each batch of fermentation.

- Check gaskets and seals:aging and leakage may cause pollution or operational risks, and should be replaced regularly.

- Lubricate moving parts:ensure that valves, rotating nozzles, etc. operate flexibly to avoid jamming.

- Monitor sensors and control panels:calibrate temperature, pressure, and flow devices to ensure accurate data.

- Regularly hire professional maintenance:at least one system-level inspection per year can prevent major failures.

FAQ

What are commercial brewing systems?

A commercial brewing system is a combination of specialized equipment used to mass produce beer, kombucha, or other fermented beverages, typically including a grinder, mash tun, lauter tun, kettle tank, fermenter, cooling system, control cabinet, and filling equipment.

What equipment does the most basic brewing system need to include?

The minimum configuration includes a mash tun, lauter tun, kettle tank, fermenter, and connecting hoses and water pumps.

What is the minimum operating space?

A microbrewery of 1-3BBL usually requires about 50-100 square meters; large systems require a more spacious environment.

Do I need to replace the entire set of equipment in the future when production increases?

Not necessarily. As long as an expandable system is selected in the early stage, fermenters can be added directly or the control module can be upgraded.

Can a commercial brewing system be customized?

Yes. Most manufacturers can customize the tank size, pipeline layout, control logic, etc. according to customer needs to adapt to different process flows and space structures.