The art of distillation is one of humanity’s oldest crafts, transforming raw agricultural materials into refined and flavorful spirits. From whiskey and rum to vodka and gin, every bottle of distilled beverage begins with a carefully managed production process and specialized equipment. For modern distilleries, distillery equipment is not only a tool for producing alcohol, but also a key factor affecting efficiency, flavor consistency, and scalability.

The Basic Principles of Distillation

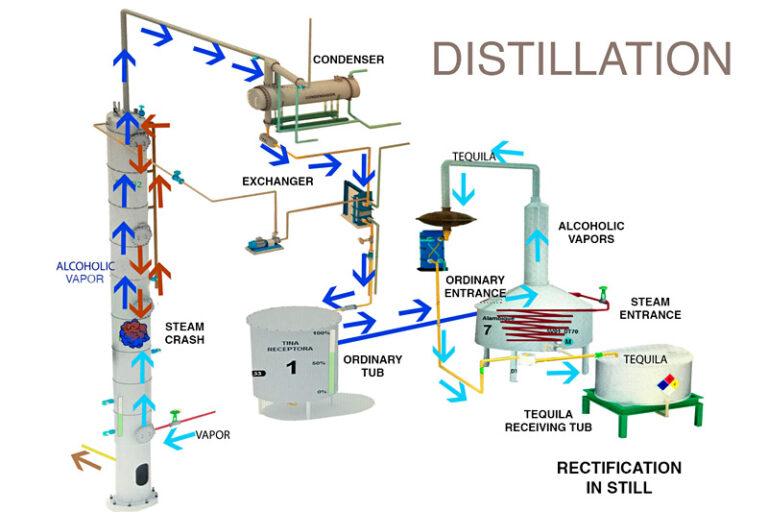

Distillation is a separation process based on the differences in boiling points between different liquid components. In alcohol brewing, a common goal is to separate and concentrate the alcohol (ethanol), while also removing some aromatic compounds. The core principle is:

- Heating the alcoholic fermentation broth;

- The alcohol vaporizes at a lower temperature, while water and other high-boiling-point substances remain in the liquid;

- The vapor is cooled in a condenser and then returned to liquid, resulting in distilled spirits.

- The key lies in temperature control and fraction separation. Different temperature zones (front still, middle still, and back still) affect the purity and flavor of the final spirit.

Main Components of Distillery Equipment

In distillation production, a complete set of equipment consists of several key parts that work together to form a complete workflow. Each step significantly impacts the flavor, purity, and production efficiency of the distilled spirit. Below, we will outline the primary components of distillery equipment and their respective roles in the process.

Pot Still (Boiler)

The pot still is the heart of the distillery equipment. Its function is to heat the fermentation liquid and vaporize the alcohol and aromatic compounds. The pot still’s shape, material, and heating method directly influence the style of the spirit. Common materials include copper and stainless steel. Copper has excellent thermal conductivity. Stainless steel is more durable and suitable for long-term use.

Distillation Columns

Distillation columns are key equipment for improving the purity of alcohol. Depending on their structure, they can be categorized as either tray-type or packed-type. Their advantage lies in their excellent separation efficiency, enabling them to produce high-purity alcohol. Therefore, they are widely used in the production of vodka, industrial alcohol, and large-scale spirits.

Gooseneck and Lyne Arm

The gooseneck is a crucial connection between the still and the condenser. Its angle and shape significantly influence the flavor of the spirit. An upward-angled gooseneck enhances the spirit’s purity, while a downward-angled one allows the spirit to retain more of the flavors of the raw materials. For example, Scotch whisky distilleries often adjust the gooseneck’s design to control the spirit’s character.

Condenser

The condenser cools alcohol vapor and liquefies it back into liquid wine. There are two main condensation methods: the traditional coil condenser and the modern shell-and-tube condenser. Condenser efficiency directly affects the wine’s taste and impurity removal, so the condenser type is often a key consideration when selecting equipment.

Spirit Receiver

After condensation, the spirit is transferred to the spirit receiver, where it is separated into different fractions. During distillation, the spirit is typically separated into foreshot, heart, and tail. The spirit receiver is often equipped with a transparent viewing window and an automated cutting system, allowing operators to more accurately determine the distillate switching point, thereby ensuring the safety and quality of the spirit.

Control System

Modern distillery equipment is commonly equipped with automated control systems for real-time monitoring and adjustment of process parameters. These systems can display and adjust temperature, pressure, flow rate, and alcohol concentration, and can also automatically adjust heating and cooling. An efficient control system not only ensures consistent product quality from batch to batch but also reduces energy consumption and human error, making it crucial for improving production efficiency and long-term competitiveness.

A Detailed Explanation of the Distillery Equipment Workflow

The distillery equipment workflow is a systematic process consisting of multiple, sequential steps. Each step plays a critical role in the purity, flavor, and safety of the resulting liquor.

Raw Material Pretreatment

Grains are typically crushed to make the starch easier to saccharify; fruit is washed, pitted, or pressed to extract the fermentable juice; and raw materials such as sugarcane are also pressed for juice. Uneven crushing or inability to remove impurities can affect the quality of the liquor.

Mashing and Liquefaction

The crushed raw materials enter the mash tank, where an appropriate amount of water is added and heated. Mashing enzymes or malt is also added. The purpose of mashing is to convert starch into glucose and maltose, which can be used by yeast. After several hours of mashing, the raw material slurry gradually transforms into a sugary liquid. The effectiveness of the mashing process directly affects the alcohol content of the mash.

Fermentation Process

After cooling, the mash is transferred to a fermentation tank and inoculated with yeast for fermentation. Fermentation typically lasts three to seven days. Different raw materials and yeast strains produce different flavor profiles. For example, fruit fermentation produces fruity aromas, while grain fermentation produces nutty or grainy notes. After fermentation, the mash typically has an alcohol content of 6%–12%, which serves as the raw material for distillation.

Heating and Initial Evaporation

After the still begins heating, the mash temperature gradually rises. Substances with lower boiling points evaporate first. The liquid discharged during this stage is typically not collected but instead discarded or recycled to ensure the purity and safety of the subsequent distillation.

Condensation and Liquefaction

After the separated alcohol vapor enters the condenser, it is cooled by cooling water or a refrigerant system, converting it back into liquid alcohol. The efficiency and cooling rate of the condenser will affect the style of the wine. While the condensation process may seem simple, it directly affects the flavor of the wine. Therefore, different wineries will choose different condenser structures based on their needs.

Storage and Aging

The middlings enter storage tanks for further processing. For products like vodka and baijiu, they can be directly filtered, reduced in alcohol, and bottled for sale. Whiskey, brandy, or rum, however, requires aging in oak barrels. During the aging process, they gradually absorb components like tannins and vanillin, developing their unique color and aroma.

Types of distillery equipment

Type | Characteristics | Suitable Applications | Advantages |

Column Distiller | Uses repeated evaporation–condensation cycles for fractional distillation | High-purity spirits production, such as vodka and gin; suitable for continuous distillation | High distillation efficiency, energy-saving, precise control of purity |

Pot Still / Kettle Still | Traditional single-pot distillation with a large boiler and distillation head | Traditional spirits emphasizing flavor, such as whiskey and brandy | Simple process, good flavor retention, but relatively low output |

Hybrid Distiller | Combines the advantages of column and pot stills, with a pot body plus distillation column | Spirits requiring both flavor preservation and high purity | Multi-functional, balances output and flavor, allows flexible adjustment of distillation effect |

Multi-functional Distiller | Can perform distillation, fractional distillation, concentration, reflux, and other processes | Small-to-medium-sized distilleries or R&D centers | One unit suitable for multiple types of spirits or experimental purposes, highly flexible |

Continuous Distiller | Raw materials are continuously fed; distillate continuously collected | Industrial large-scale production | High output, saves time and labor, stable process |

Lab or Mini Distiller | Small capacity, simplified functions | R&D experiments, home brewing, small-scale trials | Flexible, energy-saving, convenient for small-scale experiments and process development |

Vacuum Distillation | Lowers system pressure to reduce boiling point, protecting heat-sensitive substances | Craft spirits, flavor extracts, medicinal spirits, heat-sensitive ingredients | Preserves flavor, reduces thermal decomposition, suitable for heat-sensitive materials |

FAQ

What are the heating methods used in distillery equipment?

Common heating methods include electric, steam, and gas.

Electric heating is precise and easy to automatically control, providing uniform heat distribution, and is suitable for large-scale continuous distillation. Gas heating offers a fast response, but requires strict monitoring of the heating power to prevent overheating.

When choosing a heating method, consider production scale, operating costs, and safety.

How can we ensure the flavor and quality of distilled spirits?

- To ensure the flavor and quality of distilled spirits, we must pay attention to the following aspects:

- Strictly control the fermentation temperature and time;

- Select the appropriate type and operating method of distillery equipment.

- Precisely control the heating and cooling processes to avoid excessive temperatures that damage the aroma.

- Use high-quality ingredients and keep the equipment clean to prevent the development of off-flavors.

How should distillation equipment be cleaned and maintained?

Distillation equipment requires regular CIP (cleaning-in-place) operations, which involve circulating cleaning of pipes, distillation columns, and condensers to prevent residue accumulation that affects the taste of the liquor. Routine maintenance includes checking seals, valves, and heating systems, and promptly replacing aging components to ensure long-term, stable operation.

Are the investment and operating costs of distillation equipment high?

Investment costs depend on the equipment size, material, and degree of automation. Small laboratory equipment is relatively inexpensive and suitable for R&D and testing. Large industrial distillation equipment requires a higher investment, but offers high production capacity, low energy consumption, and high efficiency. Operating costs include energy consumption, cleaning and maintenance, labor, and raw material costs. Proper planning and automated control can effectively reduce long-term expenses.