Driven by the global craft beer craze, more and more entrepreneurs and catering brands have embarked on the road of home brewing. Whether you are a brewer new to the industry, a brewpub owner who focuses on customer experience, or an export brand facing the international market, choosing the right beer brewing equipment is the first step to career success.

What is beer brewing equipment?

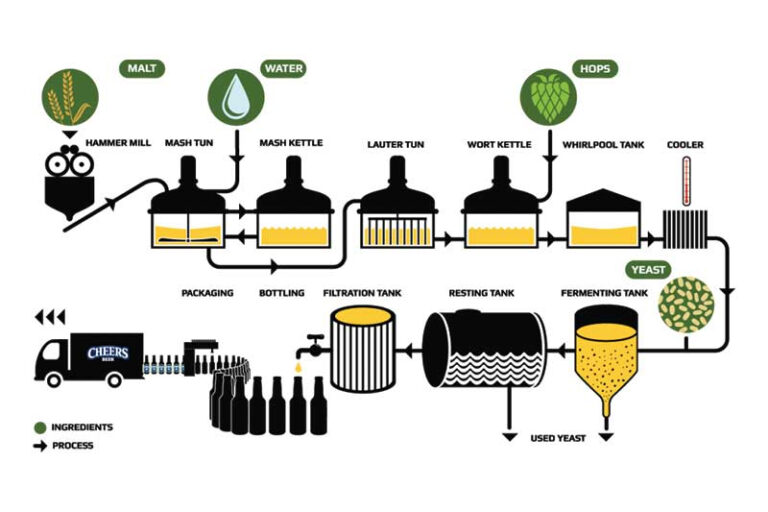

Beer brewing equipment is a complete set of special systems that convert raw materials such as malt and hops into beer. It is widely used in craft breweries, restaurants and bars, and industrial production. Compared with traditional manual brewing, modern equipment has significant advantages such as high efficiency, stability, and controllability. It not only improves the brewing quality and consistency but also greatly improves production efficiency. It is the key foundation for realizing large-scale and standardized beer production.

Core components of beer brewing equipment

A complete beer brewing equipment system must cover every key link from raw material processing to fermented finished products. Whether you are building a small nano brewery or a commercial-grade craft brewery, these equipment components are indispensable.

Malt Mill

The malt mill is the starting point of the whole system. It is responsible for crushing the malt into a particle size suitable for mash. The uniformity of malt crushing directly affects the mash efficiency and the final flavor of the beer.

Mash Tun

The mash tun is the “core battlefield” of beer brewing. It mixes malt with hot water and heats it so that starch is decomposed into fermentable sugars under the action of enzymes. This process determines the alcohol content, taste, and aroma of the beer.

Small systems mostly use electric heating, which is easy to install; medium and large systems recommend steam jacket heating, which not only heats evenly but also supports multi-stage program control of mash. Modern mash tuns are also often equipped with stirring motors and automatic temperature control systems to ensure the stability of the mash curve.

Lauter Tun

After mash, the wort must be separated from the husk, which is done by the lauter tun. The ideal lauter tun should have efficient separation capabilities and be not easily clogged, ensuring that the liquid can be smoothly discharged.

Kettle & Whirlpool

The task of the kettle is to heat the wort, kill bacteria, precipitate protein, and add hops at the right time to give the beer a unique aroma and bitterness. This step directly determines the stability and aroma performance of the beer.

Fermentation Tank

The fermentation tank is a key device for converting wort into alcoholic beverages, where yeast performs sugar conversion reactions. The design of the equipment directly affects the fermentation temperature control, yeast activity efficiency, and cleaning convenience.

Cooling System

Before fermentation, the wort must be quickly cooled from boiling to below 20°C, otherwise, the yeast cannot survive. The cooling system consists of a plate heat exchanger, an ice water tank, and a refrigeration unit, and is an important part of ensuring process hygiene and efficiency.

CIP system

Cleanliness is crucial for breweries, especially for modern craft brewing, which pursues the ultimate in flavor and hygiene. The CIP system can realize the automatic cleaning and disinfection of fermentation tanks, mash tanks, and pipeline systems.

Control system

The control system is the “brain” of the entire brewing equipment. It not only connects various subsystems for operation, but also is responsible for core functions such as process management, temperature regulation, and fault alarm.

Filling system

The finished beer needs to be transferred into bottles, cans, or draft beer barrels through the filling system. This system directly determines the product turnover speed and the quality of the outer packaging and is the last link in achieving a closed business loop.

Filling equipment is divided into bottling lines, canning lines, and barrel systems according to different packaging forms.

Choose the right size and configuration of beer brewing equipment

Nano Brewery

- Target capacity: 100L-500L/batch

- Applicable people: Startup Brewer, home brewing, small start-up projects, experimental breweries

- Key features: compact space, medium degree of automation, strong scalability

Recommended configuration:

- 2-pot or 3-pot system (mashpot + boiling pot + filter pot in one or separate)

- Vertical fermentation tank, volume 200~1000L

- Optional mobile CIP system

- The control system supports basic data recording

Small Brewpub

- Target capacity: 500L-2000L/batch

- Applicable people: Brewpub, beer brands combining catering

- Key features: strong appearance design, strong display, full functions

Recommended configuration:

- 3-pot system (mashpot + filter tank + boiling/whirlpool pot)

- Glass appearance or copper-clad stainless steel shell

- Fixed CIP, cooling tower, or chiller

- The control system supports multi-stage mash and temperature-controlled fermentation

Commercial Brewery

- Target capacity: 3000L-20000L/batch

- Applicable people: Export Brand, local/regional brand, export-oriented craft beer

- Key features: high efficiency, continuous production, standardized management

Recommended configuration:

- 4-pot system (mash, filtration, boiling, vortex separation)

- The wine storage tank + bright beer tank configuration is perfect

- Fully automatic CIP, remote monitoring

- Matching automatic filling line (bottle, can, KEG)

Comparison of domestic and imported beer brewing equipment

Comparison Dimensions | Domestic equipment | Imported equipment |

Initial investment | Lower cost and faster delivery | High cost and long transportation cycle |

Personalization | Highly flexible and deeply customizable | Modules are standardized and not easy to modify |

Technical Level | On par with international mainstream | Mature technology and strong systematization |

After-sales service | Fast local response and smooth communication | Overseas technical support cycle is long |

Certification support | CE, ISO, etc. available | Complete international certification, suitable for export |

Choose a better beer brewing equipment manufacturer

Provide design services

Design assistance from equipment manufacturers is essential. Plant CAD planning is a basic service of design assistance, which can help customers optimize space layout and ensure efficient operation and convenient maintenance of equipment. Through precise layout, customers can reasonably arrange functional areas such as the brewing area, fermentation area, packaging area, etc. to maximize the use of plant space.

MICET will provide a full set of beer brewing equipment services, including the entire brewing flow chart, tank assembly drawing, floor plan, and electrical diagram.

MICET provides technical support, site surveys, brewery R&PID process, brewery space layout design in 3D plant and CAD drawing, and turnkey brewery services.

Brewing formula technical support

Formula assistance is one of the important services of equipment manufacturers, especially in technical guidance on malt, yeast, mash process, etc. An experienced equipment supplier can provide customers with professional formula optimization suggestions.

MICET has established long-term cooperative relations with domestic and foreign raw material manufacturers and has long provided high-quality beer production raw materials, covering domestic and foreign brand beer raw materials, malt, hops, yeast, etc.

Beer formulas cover more than 50 kinds of beer, including Lager, Ale, Stout, Draft/Draught, IPA, whole wheat beer, Hoegaarden white beer, etc.

Personalized customization

Many beer brands want their equipment to match their brand image, which requires manufacturers to provide customized services. For example, copper-clad mash pots fermentation tanks, and LOGO displays can enhance brand recognition.

MICET can provide personalized customization services, from business plans and overall layouts to brewery equipment design, flow charts and layouts, and logos. We will ensure that your brewery meets your and the industry’s needs in terms of efficiency, design, production, and quality.

Provide installation and training services.

More and more equipment suppliers are beginning to provide professional overseas installation and training services to international customers. For multinational breweries, English technical manuals and English training materials are essential. These manuals not only include operating instructions for the equipment, but also include troubleshooting, maintenance, and other content to ensure that customers can quickly get started and operate efficiently.

MICET provides installation and commissioning services;

MICET factory numbers and marks all pipelines to solve any problems you encounter during the installation process.

MICET provides installation and maintenance manuals and pipeline installation layout drawings.

FAQ

What degree of automation does beer brewing equipment support?

There are three types:

- Manual control: flexible operation and low-cost

- Semi-automatic control: basic data can be controlled, suitable for start-ups

- Fully automatic control (PLC): stable, efficient, suitable for mass production and remote management

Does the fermentation tank need to be separated from the mash system?

Yes. The mash system is used for word processing, while the fermentation tank is where the yeast works. The separation design can improve production capacity, batch efficiency, and temperature control accuracy.

What are the main materials of beer brewing equipment? Which one is better?

The main material is food-grade 304 or 316 stainless steel. 304 is suitable for most beer styles and has good corrosion resistance; 316 is suitable for more acidic environments and has a higher price.

What is the most critical temperature control link in the brewing process?

Fermentation temperature control is the most critical link. The equipment usually achieves precise temperature control through jacket cooling, temperature control instruments, and cold water/ethylene glycol systems to prevent the beer from becoming sour or smelly.