With the continuous rise of craft beer culture, an increasing number of entrepreneurs and breweries are turning their attention to commercial craft beer production. However, to stand out in the fiercely competitive market, in addition to high-quality brewing recipes and effective brand marketing, selecting the right craft brewery equipment solution is also crucial.

What is craft brewery equipment?

Craft brewery equipment refers to a complete set of process equipment used for high-quality beer brewing. Unlike industrial large-scale brewing, craft brewing equipment emphasizes precise control of each process, allowing brewers to flexibly adjust temperature, time and ingredient ratios according to different recipes, thereby brewing beer with unique flavor and distinctive personality. This type of equipment is mostly made of stainless steel and is suitable for commercial scenarios such as bars, restaurants, and breweries that have higher requirements for beer quality.

Why do breweries need professional solutions?

The biggest difference between commercial craft brewing and home brewing lies in production scale, process stability, and product consistency. Commercial craft breweries usually need to meet the following requirements:

- Large-scale output: daily processing volume ranges from hundreds of liters to thousands of liters.

- Automation and process control: improve efficiency and reduce human errors;

- Food-grade safety and hygiene: meet HACCP/GMP standards;

- Diversified brewing needs: support multiple styles such as IPA, lager, wheat beer, etc..

- Energy consumption and cost control: improve energy utilization and save operating costs.

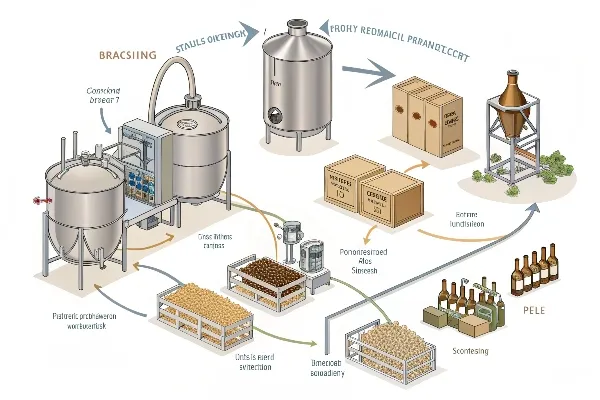

Commercial craft brewery equipment composition

Malt Mill

Malt milling is the first step in the brewing process and directly affects the mash efficiency. Commercial mills mostly use a double-roller or four-roller design, which can adjust the gap according to the type of malt to ensure uniform grinding and not over-crushing, so as to facilitate wort extraction. High-end milling equipment is also equipped with dust covers and automatic feeding systems to improve work efficiency and keep the production environment clean.

Mash & Lauter Tun

The brewhouse system is where malt is converted into sugars, usually consisting of a mash tun and a lauter tun. The mash tun is responsible for controlling temperature, stirring, and enzymatic reactions, while the lauter tun is used to separate the dregs from the wort to obtain a clear first wort. Modern mash systems are usually equipped with stainless steel jacket insulation, variable frequency stirring, automatic temperature control, and liquid level display, which help improve mash accuracy and repeatability.

Kettle & Whirlpool

The kettle is used to sterilize, concentrate the wort, and add hops, which is crucial to the formation of beer aroma and bitterness. After boiling, the wort will enter the whirlpool. Commercial systems mostly use electric heating or steam heating, and support automatic hop addition and foam control.

Plate Heat Exchanger

After the wort is boiled, it needs to be cooled to the temperature required for fermentation in a very short time. Plate heat exchangers are usually used for rapid cooling. Industrial-grade cooling equipment can perform two-stage cooling, which is efficient and energy-saving. Some high-end systems also support automatic temperature control loops to prevent temperature fluctuations from affecting yeast activity.

Fermentation Tank

Commercial breweries often use stainless steel conical bottom tanks with cooling jackets, which have good heat preservation and cleanability. The tank body is generally equipped with CIP spray balls, sampling ports, pressure gauges, exhaust valves, etc., which are convenient for daily operation and monitoring. After fermentation, the beer is usually transferred to bright beer tanks for secondary clarification and carbonization.

CIP cleaning system

No matter how good the process and raw materials are, if the cleaning is not in place, the quality of beer will be affected. The CIP system cleans the pipes of each equipment and the inside of the tank through high-temperature alkali solution, acid solution, or clean water circulation. The CIP system usually includes a double tank or three-tank structure, and the fluid circulation is driven by a centrifugal pump to effectively remove residues and microorganisms.

Control system

To ensure process consistency, commercial breweries are generally equipped with automated control systems. PLC or touch-screen operation panels can realize functions such as mash temperature setting, pump speed control, and one-button start of cleaning programs, effectively reducing human errors. Some control systems also support data collection and remote monitoring, which is a powerful tool for improving production management efficiency.

Filling system

Commercial breweries can choose semi-automatic or fully automatic filling lines, covering processes such as bottle washing, filling, capping, labeling, and coding. Depending on the product form, the filling line can be adapted to glass bottles, aluminum cans, or PET bottles, providing flexible support for different market needs.

How to choose the right commercial brewing equipment solution?

For breweries of different sizes and market positioning, the equipment configuration solutions are also different. The following core elements can help users make wise choices:

Capacity planning

- Small commercial use (500L~1000L): suitable for craft breweries, community breweries

- Medium-sized production (1000L~3000L): suitable for urban breweries, e-commerce brands

- Large-scale industrialization (more than 5000L): suitable for bulk supply and export markets

Automation level

- Semi-automatic system: suitable for teams with a limited budget but experience in the brewing process;

- Fully automatic system: suitable for commercial enterprises pursuing stability and efficiency.

Expansion Capability

The modular design makes it easy to add fermentation tanks, expand production capacity, or connect to canning production lines in the future, avoiding repeated investment.

After-sales and service support

Choosing equipment suppliers with rich export experience and local technical services can provide strong guarantees in equipment installation, commissioning, training, maintenance, etc.

Budget and Space

Brewery Type | Investment Budget | Required space range |

50000~100000$ | Approximately 500 to 1,000 square feet | |

Small Breweries | 150000~500000$ | Approximately 1,000 to 5,000 square feet |

Medium-sized craft brewery | 300000~700000$ | Approximately 5,000 to 10,000 square feet |

Large commercial brewery | 70 0 0000$ | 20,000 sq. ft. and up |

How to choose the right brewery equipment supplier?

Quality and cost

Although some equipment is cheaper and can save investment in the initial stage, it often means higher maintenance frequency, shorter service life, and even the risk of production interruption. In contrast, although equipment manufacturers in Europe and the United States are more expensive, they are more guaranteed in terms of materials, workmanship, and long-term stability. The wise choice is to find a supplier that strikes the best balance between quality and cost, rather than blindly pursuing low prices.

Equipment customization

A high-quality equipment supplier should be able to provide customized solutions based on your brewing scale, target market, product type, and budget requirements. This includes not only flexible adjustment of equipment configuration, but also detailed operation manuals, employee training programs, and a fast-response after-sales service system. A truly reliable supplier will help you solve every detail from installation to production like a partner.

Reputation and reputation

Before making a decision, be sure to fully understand the supplier’s market reputation through customer reviews, field visits, industry exhibitions, or professional forums. Choosing a supplier with a good delivery record, high customer satisfaction, and a complete service system will lay a solid foundation for your winemaking project. Especially those manufacturers with many years of industry experience are more trustworthy.

FAQ

What is a brewery?

A brewery is an industrial facility dedicated to the large-scale production of beer, equipped with professional brewing equipment and production lines to achieve commercial brewing processes.

What equipment is needed for beer production?

Key equipment includes: brewhouse system, fermentation tank, cooling system, filtration equipment, filling and packaging machine, etc.

Are all modern breweries automated?

Many modern breweries have widely adopted automation systems and intelligent control technologies to improve production efficiency and consistency of brewing quality.

What is the difference between commercial craft brewing equipment and home brewing equipment?

The main differences are capacity, degree of automation, production efficiency and compliance standards. Commercial equipment has larger capacity, higher precision temperature control and automation systems, and meets food-grade hygiene requirements. In contrast, home equipment focuses more on simplicity and has relatively streamlined functions.