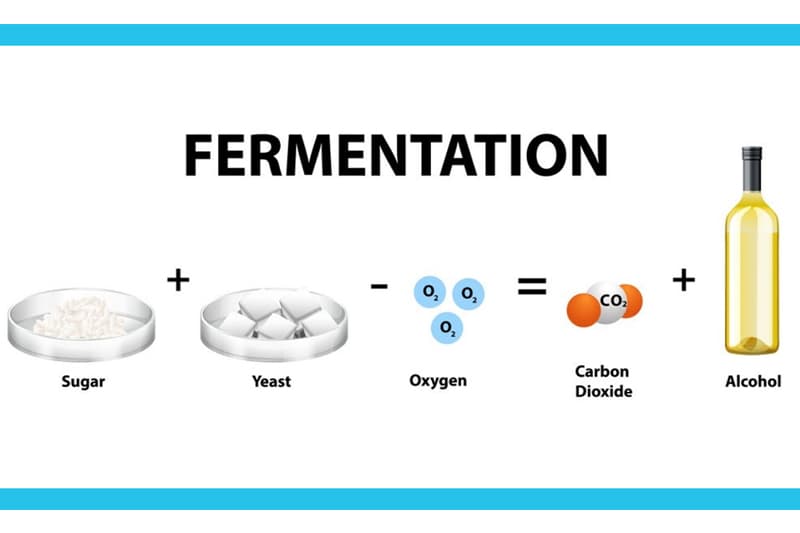

Fermentation is the process by which yeast converts the glucose in the wort into ethanol and carbon dioxide gas. Fermentation provides the alcohol content and carbonation of the beer. Before fermentation begins, the cooled wort needs to be transferred to a container with yeast added. Fermentation is usually divided into three stages: primary, secondary, and conditioning (or storage). If the brewed beer is malt wine, the wort needs to be kept at a constant temperature of 68 degrees Fahrenheit (20 degrees Celsius) for about two weeks. If the beer is a lager, the temperature needs to be kept at a constant temperature of 48 degrees Fahrenheit (9 degrees Celsius) for approximately six weeks. Because the fermentation process generates a lot of heat, the tank must be constantly cooled to maintain the proper temperature.

Beer fermentation process

Primary fermentation

The primary stage of fermentation begins when the yeast is introduced into cooled, aerated wort. The yeast quickly utilizes the available oxygen to produce sterols, a vital compound for culture expansion. When the oxygen is gone, the yeast switch to the anaerobic phase where the majority of wort sugars are reduced to ethanol and CO₂. Yeast growth occurs during primary fermentation. The extent and rate of yeast growth are directly related to the production of aroma and flavor compounds.

Primary fermentation effect

- Depletion of dissolved oxygen

- Acidification/reduction in PH

- Yeast growth or culture expansion

- Ethanol and CO₂ production

- Production of flavor compounds such as esters, diacetyl, sulfur-containing compounds, etc.

- Consumption of most wort sugars

The temperature of the primary fermentation should be regulated according to the desired flavor and aroma profile. The following is a guideline:

Primary fermentation temperatures

- Ales: 62-75 °F (17-24 °C)

- Wheat and Belgian styles: 62-85 °F (17-29 °C)

- Lagers: 46-58 °F (8-14 °C)

Note:

Lager fermentation tank is started warmer (~60 °F/15.5 °C) until signs of fermentation (gravity drop, CO₂ production, head formation) are evident. Cool to desired fermentation temperature once signs of fermentation are observed.

Secondary fermentation

The secondary stage of fermentation refers to the stage of fermentation after the majority of the wort sugars have been consumed and there is a sharp decrease in the rate of fermentation. During this period, most of the final sugars are depleted and some secondary metabolites are converted by the yeast. Yeast flocculation and settling begin to occur due to the increase in alcohol content and the depletion of sugar and nutrients. Diacetyl reduction takes place during secondary fermentation and during the diacetyl rest that some brewers incorporate into the secondary stage of fermentation.

Secondary fermentation effect

- Decreased rate of ethanol and CO₂ production

- Diacetyl Conversion

- Reduction of some flavor compounds by yeast metabolism or CO₂ scrubbing

- Terminal gravity is reached

- Yeast flocculation and settling begins

Secondary fermentation temperatures

- Ales: Same as primary fermentation (higher temperatures will increase diacetyl reduction rates)

- Lagers: 40-60 °F (4-15 °C). Some brewers allow the beer to increase in temperature to speed the diacetyl reduction. This increased temperature is usually only sustained for 24 to 48 hours.

- Wheat and Belgian Beers: Same as primary fermentation (higher temperatures will increase diacetyl reduction rates).

Conditioning

The conditioning stage takes place when the terminal gravity has been reached and the tank is cooled to refrigeration temperatures (31-38 °F, 0-3 °C). During this time the yeast continues to flocculate and settle. The yeast also conditions the beer by reducing various undesirable flavor compounds. Ales do not enjoy long conditioning times as lagers do. The desirable flavors in ales will decrease with age and thus it is recommended that conditioning be as short as possible before packaging. Exposure to oxygen at this stage is extremely detrimental to beer quality.

Conditioning effect

- Most of the yeast is removed from the beer

- Formation and precipitation of haze forming proteins

- Reduction and mellowing of harsh flavors

- Reduction of sulfur compounds, diacetyl, and acetaldehyde

- Flavor stabilization

Selection of fermentation vessel

Fermentation can be carried out in various forms of containers, open stone containers can be used, or wooden barrels can be selected. Now, most breweries choose conical vessels or CCV (Conical cone vessels, also called fermentation tanks), which have a conical bottom and a cylindrical top. The angle of the cone-shaped vertebral body is usually about 60°. This angle allows the yeast to flow to the top of the vertebral body, which facilitates the recovery of the yeast for reuse. Of course, some other configurations can be added to the fermentation tank, so that the beer can be processed in the same tank for fermentation and conditioning.

Fermentation can also use open fermentation vessels, usually used in beer bars, and in Europe for the fermentation of wheat beer. The open container has no top, which makes it very easy to harvest top-fermenting yeast. But, the use of open containers has a great risk of infection and requires proper cleaning procedures. Also, you can also use simple cylindrical tanks and place them vertically. Of course, there are very few breweries that still use wooden barrels for fermentation. But, the wood is difficult to keep clean and free of infection, and it is replaced at least once a year.

Factors affecting beer fermentation

How long can beer be fermented? Many novice brewers want to know the best time frame for fermenting beer. In fact, we have no way to accurately know the fermentation time. When we put yeast into the wort, the yeast will do all the work. But, we can change certain conditions to extend or shorten this time range, such as controlling the fermentation temperature and the type of yeast.

The impact of raw materials

- The influence of malt: the quality of malt directly determines the content of α-amino nitrogen in the wort and the amount of fermentable sugars. This will affect the yeast’s demand for nitrogen sources and the decomposition of sugars, and affect the degree of fermentation of beer.

- The impact of brewing water: the lack of minerals and trace elements in the brewing water will also limit the growth of yeast.

The impact of the mashing process

Mashing temperature: use 62 degrees Celsius and 70 degrees Celsius segmented mashing method to extend the mashing time to 62 degrees Celsius and shorten the mashing time to 70 degrees Celsius. The mashing temperature of about 62 degrees Celsius can maximize the effect of β-amylase to form more fermentable sugars such as glucose, maltose, fructose, sucrose, and maltotriose. So, the mashing time at 62 degrees Celsius can be prolonged to get a higher degree of fermentation. The mashing temperature of about 70 degrees is conducive to the role of α-amylase. But, it will lead to an increase in low molecular dextrin content, low fermentable sugar content, and low fermentation degree. So, it is necessary to shorten the mashing time to 70 degrees.

The influence of wort PH value

Omit to mash, the best pH for protein resting is 5.2-5.4, and the best pH for mashing is 5.5-5.6 so that the enzyme can fully function.

Influence of wort concentration

The concentration of wort is too thick or too thin will affect the starch hydrolysis or the accumulation of fermentable sugar.

The impact of mashing operations

Omit protein resting and saccharification, it should be stirred every 15-20 minutes, usually 5-8 cycles/time. Such an operation is not only conducive to the uniformity of the wort temperature, to make up for the lack of probe installation position, but also conducive to the action of enzymes.

Effects of protein cessation

After feeding, the protein is stopped at 45° for about 30 minutes. This can meet the yeast’s demand for nitrogen sources and ensure the normal progress of fermentation.

The influence of the fermentation process

Properly increase the main fermentation temperature, extend the main fermentation time, and control the appropriate fermentation temperature and time at the same time, which can increase the degree of fermentation. Wort oxygenation and yeast inoculum directly affect yeast activity and fermentation speed. Generally speaking, the higher the temperature, the more violent the yeast movement and the faster the fermentation speed. But, each type of yeast has a specified temperature range. When the fermentation temperature exceeds the specified range, peculiar smells and undesirable characteristics may be produced in the beer. When the fermentation temperature is lower than the specified range, the yeast will slow down the activity, or even stagnate. So, you need to control the fermentation temperature within the temperature range of the yeast.

The 5 stages of yeast in the fermentation process

Yeast adaptation stage (0-15 hours)

The newly inoculated yeast has to adapt to the new environment. Now, there will be many stages where the number of cells does not increase. This stage is called the yeast adaptation stage. During this stage, a certain active substance in the cell failed to reach the smallest concentration required for cell division. So, there is an “adaptation period” before the yeast growth stage. The length of the adaptation period is related to the condition of the microorganisms and the nature of the culture medium.

Yeast growth stage (4 hours-2 days)

After the adaptation phase is over, the yeast has adapted to the new environment and the cells enter the growth phase of rapid reproduction. At this stage, the cells grow at the fastest rate, and the number of cells rises almost linearly.

Growth deceleration stage (2-4 days)

With the continuous growth and reproduction of yeast cells, factors such as insufficient substances and continuous accumulation of harmful products, insufficient oxygen supply, or insufficient growth space for yeast may occur. These factors will slow down the reproduction speed of cells and enter a deceleration period.

Yeast stable stage (3-10 days)

After the deceleration period, the growth of the cells will gradually stop, the growth curve will stabilize, and enter the fourth stage-the stable period. The total number of living cells remains constant during the stationary phase. This may be because the number of new cells produced by division is equal to the number of dead cells, or the cells just stop dividing and still maintain metabolic activity.

Yeast death stage (several weeks)

With the consumption of nutrients and the accumulation of harmful substances, the environmental conditions continue to deteriorate, leading to a continuous decline in the number of living cells and cell growth into the death phase.

Yeast autolysis

Yeast autolysis refers to a phenomenon in which the enzymes of yeast cells decompose carbohydrates and nitrogen-containing substances in yeast cells to destroy the structure of yeast cells. Finally, the contents of the cells enter the beer.

Consequences of yeast autolysis

- Beer has a yeasty taste;

- The PH value of wine rises (the dissolution of basic amino acids);

- Deterioration of product biological stability;

- The non-biological stability of the product has deteriorated;

- Beer foam performance deteriorates.

Causes of yeast autolysis

- During the post-cooking process, the temperature is very high;

- The number of yeast is high when the wine is stored at a low temperature, and the wine storage time is long;

- Excessive pressure ruptures the cells;

- Improper storage of yeast;

- When the yeast recovery tank is performing yeast recovery, the reserve pressure is too low or there is no reserve pressure;

Get a quotation for beer brewing equipment

If you plan to start your own commercial brewing plan, you can contact Micet Craft for a quote. Micet Craft is one of the best brewery equipment manufacturers in China, and we can provide you with a turnkey solution. Of course, we can also customize the design and production of brewery equipment according to your requirements. We very much hope to be able to help you.