How does water affect the taste of beer?

Since beer is about 90% water, the quality and composition of the water will have a huge impact on the flavor of the beer. Three elements of water affect the taste of beer: mineral content, pH, and alkalinity. The hardness and mineral content of the water impart flavor and affect the fermentation process. The pH value favors enzymatic action in the mash and promotes the proliferation of yeast during the fermentation phase. Alkalinity creates a buffer that protects the pH from fluctuations throughout the brewing process, ensuring bacteria cannot grow and removing excess tannins from the beer. These three factors are inseparable and together determine the taste and color of beer.

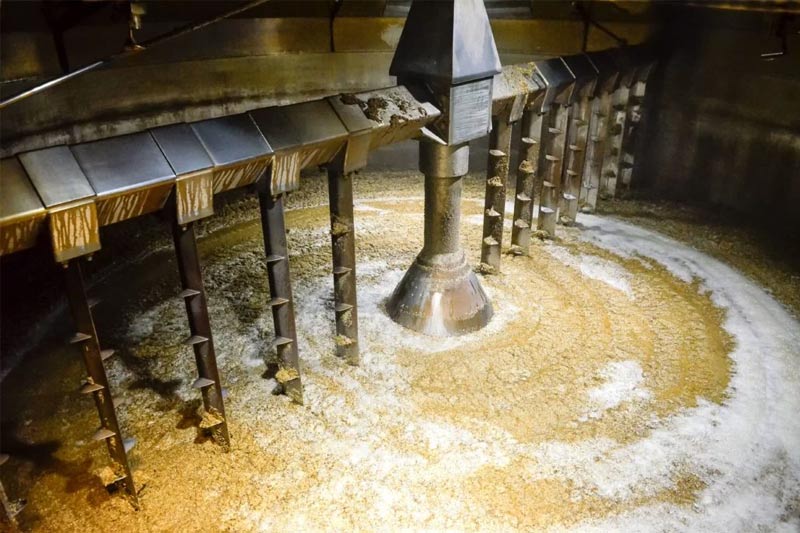

The process of steeping in hot water, called mashing, starts the brewing process and prepares the barley for fermentation. During mashing, the crushed grains are hydrated with hot water, forming a thick mixture and activating enzymes in the malt. These enzymes, alpha-amylase, and beta-amylase, convert soluble cereal starch into fermentable sugars. This fermentable liquid, called wort, is a combination of proteins and carbohydrates that affects the malt, mouthfeel, and body of the beer.

What is the source of brewing water?

- Tap water (municipal water): This is the water in your home that contains basic amounts of minerals from local reservoirs.

- Spring or bottled water: This is the water you can buy at the grocery store and contains certain amounts of minerals.

- Distilled or RO (reverse osmosis) water: This is water that has all the minerals removed, producing pure H2O.

Water treatment in brewing

What elements need to be processed?

Calcium sulfate (CaSO4)

Sodium bicarbonate (NaHCO3)

Calcium chloride (CaCl2)

Magnesium sulfate (MgSO4)